Click For Video

This automatic labeling machine is used to label self-adhesive stickers on small aluminum tube, it can automatic feed aluminum tube, label stickers, and unload aluminum tube.It can be customized for plastic soft tube and work with automatic aluminum tube filling sealing machine to realize automated production

Parameter

- Machine Model:ZS-TB160T

- Voltage:220V 50-60Hz

- Power:2KW

- Working Speed:About 30-80pcs/min(depending on tube size)

- Suitable Tube Diameter:Customize forspecific sizes

- Suitable Tube Length:Customize forspecific sizes

- Labeling Accuracy:±1mm

- Label Size:15-300mm(W)*10-130mm(H)

- Air Pressure:About 0.4-0.6MPa

- Label Roll Inside Diameter:76mm

- Label Roll Outer Diameter:100-350mm

- Application:Aluminum Tube & Plastic soft tube

- Machine Size:About 2650*1800*1920mm(L*W*H)

- Package Size:About 230*130*208mm

- Package Weight:About 673kg

Equipped with PLC touch screen control panel, the visual working data simplify the machine debugging.Rotatable control panel improves user experience.Different kinds of operation language can be customized as operation need.

Put empty soft tube into tube feeding structure, it will make tube be in order and supply them in time, with this structure, it saves working labor.

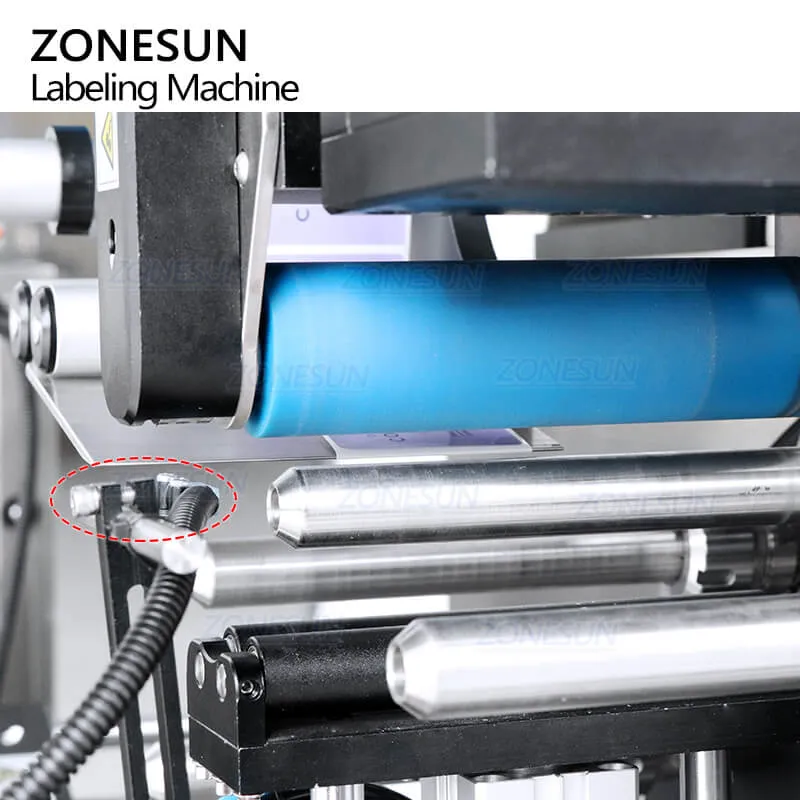

Soft tube will be rotated and stickers will be separated and sticking to the tube, the roller will press sticker during this process, ensure there is no bubble under stickers.There is an electric eye, which can be used to detecting tube and control the machine to start labeling work.

The fixing mold for sleeving soft tube can be customized according to tube sizes, changing the mold can be used for different size of tubes.This ensures the labeling accuracy.